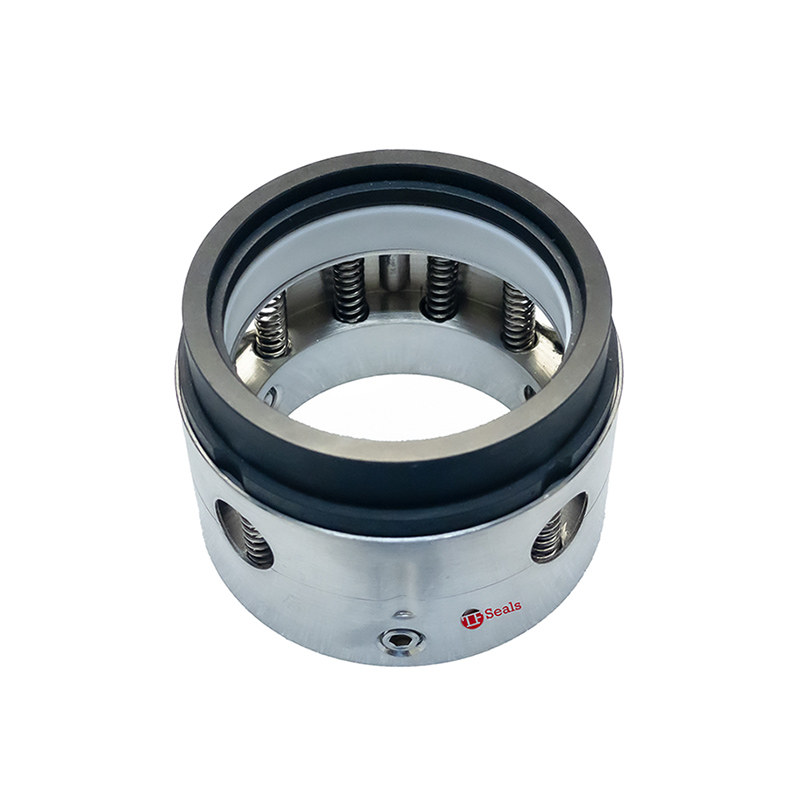

Diamond is forever! TF REAL DIAMND, applied to mechanical seal faces through Chemical Vapor Deposition (CVD) technology, offers exceptional protection for rotating surfaces. Boasting unmatched hardness, exceptional resistance to chemical attack, and ultra-low friction, this diamond coating significantly reduces wear and extends the lifespan of mechanical seals.

◆Advantages:

-The largest known electrochemical potential window of all electrode materi-als

-low background

-Excellent chemical inertness

-Reduced fouling compared to other electrodes

-The ability to withstand extreme potentials, corrosive and high temperature/-

-pressure environments

Diamond is coated on the existing mechanical seal rings and bearings made of

silicon carbide. No extra change needs to be made to the existing seal or

bearing design. All you need to do is replacing the uncoated components with

diamond-coated ones.

◆Application:

-Petrochemical Industry

-Mining industry / slurry applications

-Pharmaceutical industry Chemical industry

-Power plant technology Special applications

| Property | NCD coatings | MCD coatings | |

| As grown | Polished | Polished | |

| Diameter | Up to 350mm | Up to 150mm | Up to 150mm |

| Coating Thickness | ≥5μm | ≥10μm | ≥15μm |

| Vickers Hardness | ≥8000HV | ≥8000HV | about 10000HV |

| Flatness | ≤1μm | ≤lμm | ≤1μm |

| Special Features | Ultra Low Friction | Ultra low friction | High Temperature/Pressure,and Dry Running |

-

Tel:

1.713.568.5547

-

Fax:

1.713.758.0388

-

Address:

21247 FM 529

Cypress, TX 77433

USA -

E-mail:

sales@TFSealsUSA.com

Copyrighte 2024 TF Seals All Rights Reserved. Privacy Policy

-

1.713.568.5547

-

sales@TFSealsUSA.com